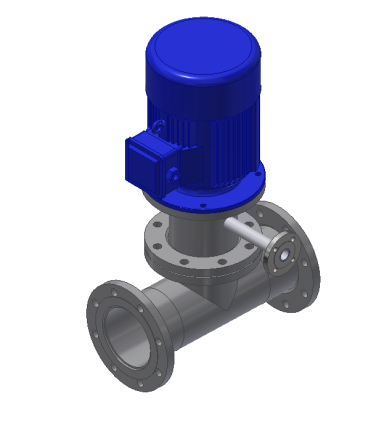

NDM/I Series Injection Dynamic Mixer: Precise flocculation dosing, reshaping the efficiency and economy of sludge treatment

The NDM/I series injection-type dynamic mixer is a highly efficient core equipment specially designed for sludge dewatering and sewage treatment processes. By instantaneously and uniformly dispersing and mixing the flocculant, it thoroughly optimizes the efficiency of the reagent usage, significantly enhances the solid-liquid separation effect, and brings customers significant cost savings in operation and an overall improvement in treatment efficiency.

Core functions: Precise injection and efficient dispersion

The flocculant is precisely injected into the flowing sludge through the hollow rotating main shaft of the mixer. Under the action of the high-speed rotating (1450 rpm) dispersion blades, the chemicals are instantaneously shears and diffuses, achieving a uniform distribution at the micrometer level. They quickly come into full contact and react with the sludge particles, effectively avoiding the problem of uneven distribution of chemicals that is prone to occur in traditional dosing methods, laying a solid foundation for the subsequent dewatering process.

Core technical advantage: Outstanding value surpassing static mixers

Significantly reduce the dosage of flocculant

The extremely uniform dispersion enables the flocculant’s activity to be fully exerted, effectively reducing the dosage of the reagent by 10% to 25%, directly lowering the continuous procurement costs for customers.

Enhance dehydration effect and reduce disposal cost

More thorough mixing reactions form larger and denser flocs, significantly increasing the solid content of the filter cake after dewatering. This not only reduces the load on the subsequent treatment but also further cuts down the cost of sludge disposal.

Significantly reduce the consumption of dilution water and wastewater discharge

With its powerful dispersion capacity, NDM/I can directly mix flocculant solutions of higher concentrations (0.5% to 1%). Compared with the low-concentration solutions (0.1% to 0.3%) required by static mixers, it can save up to 70% or more of dilution water, simultaneously reducing wastewater discharge, which is energy-saving and environmentally friendly.

Reduce the overall operating costs

The multiple reductions in drug consumption, water consumption and sludge treatment costs bring clear and considerable economic benefits throughout the entire process to customers.

The core value we bring to you

Save money: Reduce the consumption of chemicals > directly lower procurement costs;

Convenience: Increasing the solid content of the sludge cake > reducing the cost of sludge disposal;

Water and peace of mind: Reduce dilution water > Energy conservation and environmental protection, simplify the drug preparation process;

The NDM/I injection type dynamic mixer is not merely a mixing device, but also a cost reduction and efficiency improvement solution aimed at recovering investment in the short term. If you wish to further optimize the sludge treatment process and achieve sustainable cost control, please feel free to contact us at any time to obtain detailed technical solutions and economic benefit analysis.

| NDM/I | |||||

| Type | NDM/I 100 | NDM/I 150 | NDM/I 200 | NDM/I 250 | NDM/I 300 |

| Connection | DN100 | DN150 | DN200 | DN250 | DN300 |

| Speed rpm | 1450 | 1450 | 1450 | 1450 | 950 |

| Motor power kW | 1.1 | 2.2 | 2.2 | 3 | 4/5.5 |

| Viscosity cSt | 1~3000 | ||||

| Design pressures | PN16 | ||||

| Material | 304L/316L/2205/2507 | ||||

| Sealing | Mechnical Seal+Lipseal | ||||

| NDM/IInject dynamic mixer VS static mixer | |||

| Core indicators | NDM/IInject into the dynamic mixer | Static mixer | Explanation |

| Uniformity of mixing | Very high | Depending on the flow rate | |

| Adjustment of mixing intensity | Variable frequency speed regulation | Cannot be adjusted | |

| Pressure drop | Very small | big | A static mixer must have a pressure drop to mix |

| Occupied space | Very small | big | Dynamic mixers are directly installed through pipelines, while static mixers have requirements for length, straight pipe sections, etc |

| Flocculant concentration | 0.5~1% | 0.1%~0.3% | |

| Demand for dilution water | small | big | The injection dynamic mixer can be used for high-concentration dosing |

| Demand for flocculants | small | big | High uniformity of mixing and low demand for flocculant |

| Solid content in the filter cake | high | Medium | |

| Installation cost | low | high | Pipe installation is simple and easy to operate |

| Operational flexibility | high | low | The flow rate does not affect the mixing of the dynamic mixer, but the low flow rate of the static mixer makes it impossible to mix thoroughly |