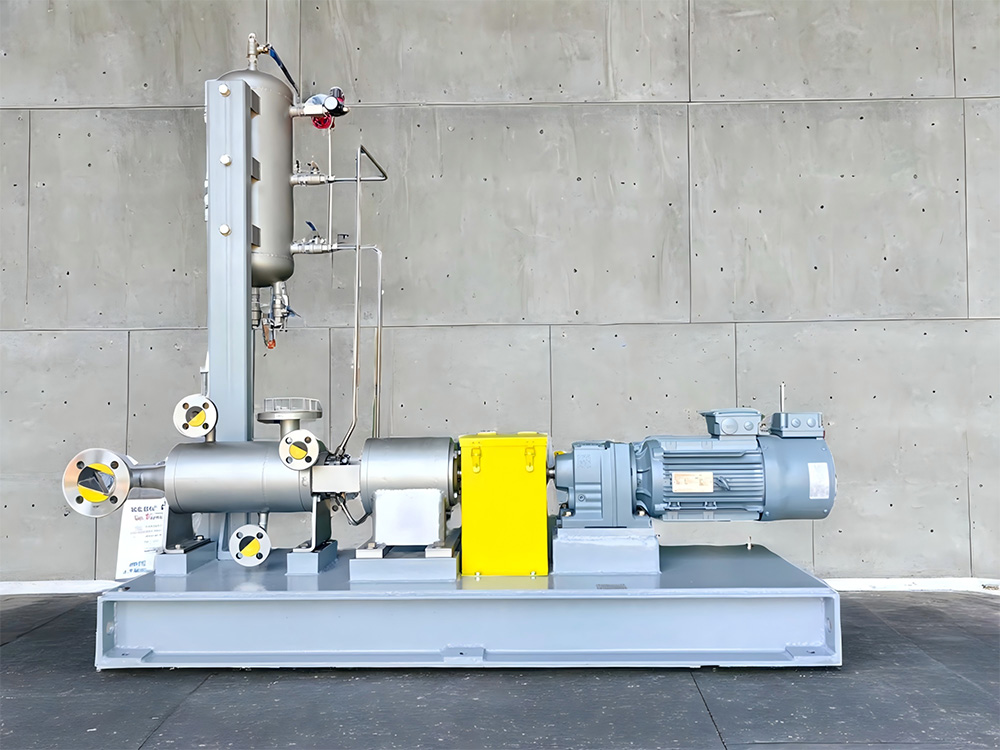

NDM/S Series dynamic mixer: An expert in high-intensity and high-efficiency dispersion and mixing

The NDM/S series dynamic mixer adopts an innovative stator and rotor collaborative shearing structure. By configuring star or pin-shaped rotors on the rotors and cooperating with the corresponding stators on the housing, a powerful mixing mechanism is achieved where the rotors move in a circular motion and the stators move in a reverse direction. This equipment is specially designed for liquid-liquid and gas-liquid mixing processes. It can achieve fine emulsification, uniform dispersion and efficient reaction of materials in an extremely short time, making it an ideal choice for high-demand mixing applications in fields such as chemical engineering, energy and pharmaceuticals.

Core functions: Powerful shearing, efficient homogenization

The NDM/S series can rapidly complete the high-speed mixing and emulsification of various materials by means of the intense shear and turbulent field formed between the stator and rotor. It is not only suitable for conventional liquid-liquid mixing, but also performs exceptionally well in handling high-viscosity materials, gas-liquid blending, and processes that require rapid reactions. In actual chemical reactions, this equipment can significantly enhance the uniformity of the reaction system and the consistency of the products. Meanwhile, under the action of strong shear, it can effectively reduce the apparent viscosity of the materials, decrease the resistance of pipeline transportation, and significantly lower the energy consumption of the system.

Typical application scenarios

Chemical reactions and dispersion: Suitable for rapid reaction processes such as polymerization, emulsification, and catalysis, improving the uniformity of products and reaction efficiency;

High-viscosity material processing: It can effectively break down the viscosity of the system, improve fluidity, reduce reliance on booster pumps, and achieve energy conservation and consumption reduction.

Gas-liquid mixing and dissolution: It is used for the efficient dispersion and dissolution of gases in liquids to enhance mass transfer efficiency.

Main technical features

Heavy-duty structure, high-intensity mixing

The equipment adopts a heavy-duty design. The rotor and stator systems feature excellent mechanical strength and wear resistance, capable of withstanding harsh working conditions such as high viscosity and high solid content.

Highly efficient and energy-saving, with rapid dispersion

The mixing effect is rapid and uniform, with energy consumption significantly lower than that of traditional stirring equipment. It has excellent self-cleaning ability, preventing material adhesion and cross-contamination.

It operates stably and is easy to maintain

The structural design is reasonable, with no risk of clogging. The main components are easy to disassemble, assemble and maintain, significantly reducing downtime.

The temperature control is flexible and suitable for various processes

Optional insulation jacket structure is available, supporting heating or cooling functions to meet the mixing and reaction requirements under different temperature conditions.

Why choose the NDM/S series?

Enhance reaction and product quality: High-speed and high-uniformity mixing ensures reaction adequacy and batch consistency;

Low comprehensive energy consumption: Effectively reduces the resistance of material transportation and the operating power of the system, achieving energy-saving operation.

Widely applied and highly adaptable: It covers a wide range of scenarios from conventional liquid-liquid mixing to highly challenging gas-liquid dispersion and high-viscosity processing.

The equipment is robust and reliable: The heavy-duty design extends its service life, reduces maintenance frequency, and offers outstanding comprehensive benefits.

The NDM/S series dynamic mixers, with their outstanding mixing performance, stable operation and wide process adaptability, have become an important choice in the high-end mixing equipment market. If you need further information on equipment selection and technical solutions, please feel free to contact our engineering team.

| NDM/S | |||||

| Type | NDM/E 80 | NDM/E 100 | NDM/E 200 | NDM/E 300 | NDM/E 400 |

| Flowrate L/h | 80~800 | 200~2,000 | 600~6,000 | 1000~10,000 | 2000~20,000 |

| Speed rpm | 100~950 | 150~1450 | 150~1450 | 150~950 | 100~950 |

| Motor power kW | 1.5~5.5 | 2.2~7.5 | 4~15 | 5.5~45 | 15~75 |

| Connection | DN80/40 | DN100/50 | DN125/80 | DN150/100 | DN200/100 |

| Viscosity cSt | 1~300,000 | ||||

| Design pressures | PN20/PN40/PN100 | ||||

| Material | 304L/316L/2205/2507 | ||||

| Sealing | Cartridge Mechnical Seal/Double Mechnical Seal/Magnetic Drive | ||||