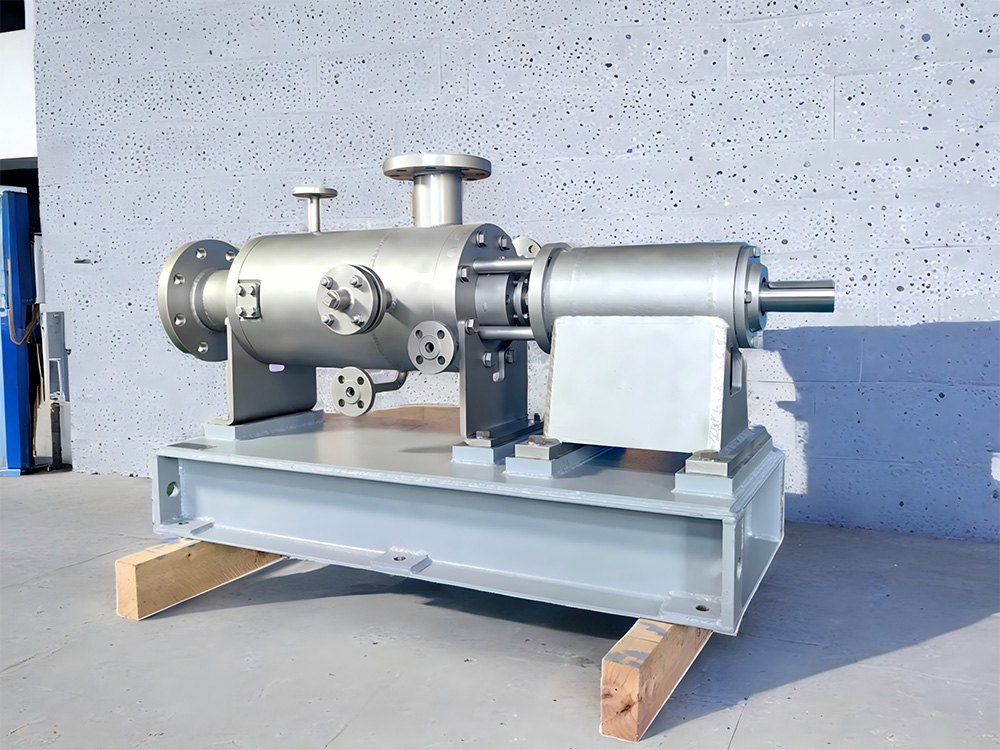

NDM/HP Series high-pressure dynamic mixer: An efficient and energy-saving solution for the production of high-viscosity polymers

The NDM/HP series high-pressure dynamic mixer is specially designed for the precise homogenization and dispersion of trace components such as additives and color masterbatches in the production process of high-viscosity polymers. This equipment can operate stably under operating pressures up to 180Bar, viscosities exceeding 1,000,000cSt, and high-temperature conditions above 300℃. With lower investment and operating costs, it efficiently replaces traditional screw extruders.

Why choose the NDM/HP series dynamic mixer?

In the production of polymer modification, coloring and functionalization, traditional screw extruders have pain points such as high equipment procurement costs and high energy consumption. The NDM/HP series achieves uniform dispersion of an extremely small proportion of additives in high-viscosity media through a high-speed stator and rotor shearing structure. Its energy consumption is only 5% to 10% of that of screw extruders, significantly reducing customers’ fixed asset investment and long-term operating costs.

Core technical features

Extremely low pressure loss

The system pressure drop is ≤5Bar, significantly reducing the load and energy consumption of the front-end transfer pump and optimizing the overall line energy efficiency.

Continuous and uniform mixing ensures stable quality

Achieve high-precision online dispersion to ensure the consistency of each batch of products and avoid agglomeration or uneven distribution.

Precision cutting and self-cleaning ability

The gap between the stator and rotor is extremely small, avoiding dead zone material accumulation. It has excellent self-cleaning properties and a long maintenance cycle.

Wear-free operation with controllable temperature rise

The non-contact design eliminates metal friction, resulting in a small operating temperature rise and making it suitable for handling heat-sensitive materials.

Flexible temperature control configuration

Optional insulation jackets or electric heating modules are available to meet the requirements of high-temperature or precisely temperature-controlled processes.

Typical application scenarios

Functional additives such as color masterbatches, antioxidants and flame retardants are added to the polymer melt.

Blending modification of high-viscosity elastomers, adhesives, silicone and other materials;

Injection and dispersion of liquid additives under high-temperature and high-pressure conditions.

Polymer chain extenders, terminators and other reactive prepolymerization mixtures.

The NDM/HP series high-pressure dynamic mixer, with its compact structure, excellent energy-saving performance and reliable mixing quality, has become an ideal choice for improving quality and reducing consumption in the polymer industry. If you wish to learn more about equipment compatibility and benefit analysis, please feel free to contact our technical team.

| NDM/HP | ||||

| Type | NDM/HP Mini | NDM/HP100 | NDM/HP 200 | NDM/HP 300 |

| Flowrate L/h | 5~80 | 50~500 | 300~1,500 | 1,000~4,000 |

| Speed rpm | 150~700 | 150~400 | 150~300 | 100~240 |

| Motor power kW | 1.5~4 | 4~15 | 15~30 | 22~45 |

| Connection | DN50/50 | DN100/100 | DN125/125 | DN150/150 |

| Viscosity | 1,000~2,000,000 cSt | |||

| Design pressures | 100/180 bar | |||

| Material | 304L/316L/2205 | |||

| Sealing | Viscoseal+Lipseal/Viscoseal+Packing | |||