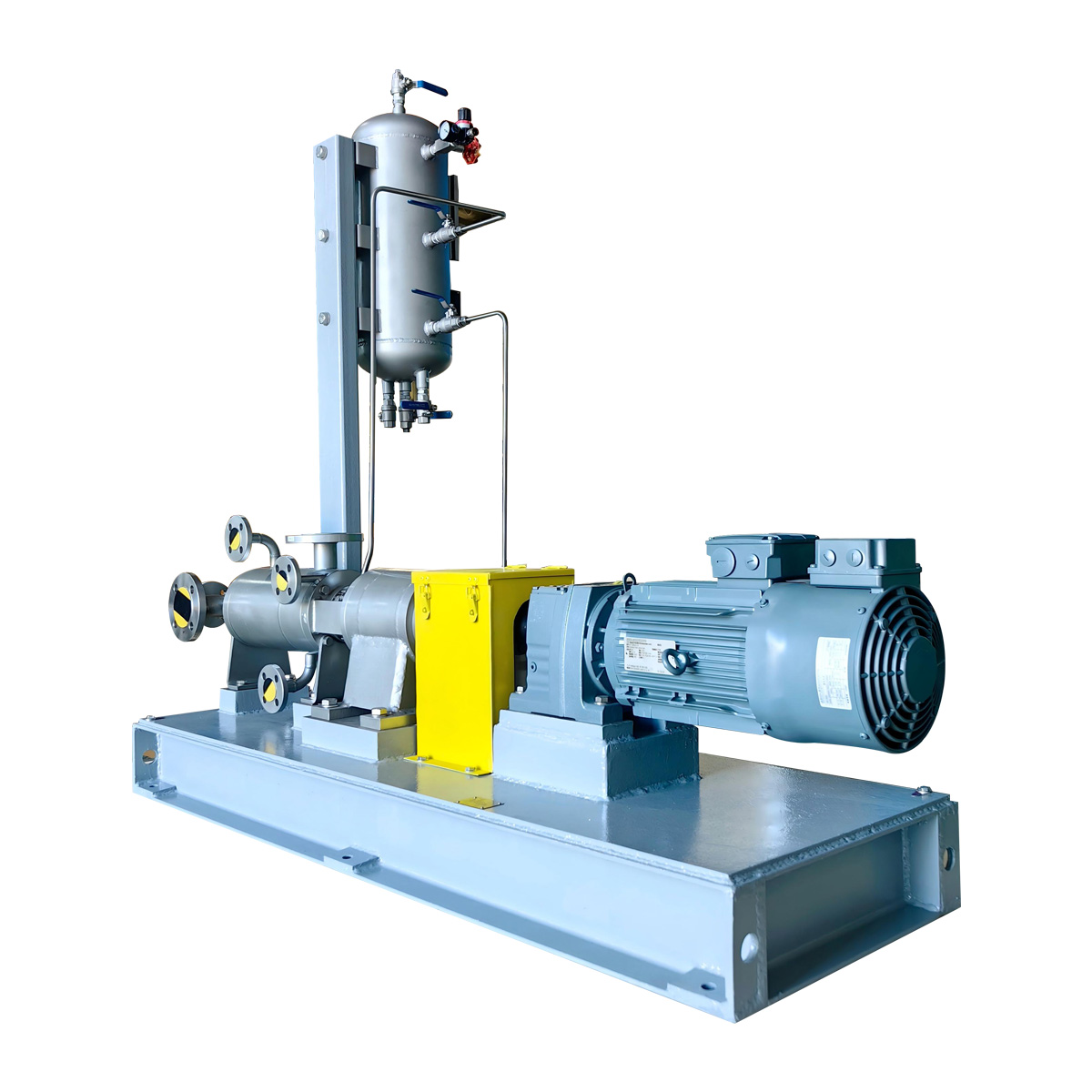

NDM/E series dynamic mixer: Gentle and efficient, a continuous mixing solution specially designed for sensitive materials

The NDM/E series dynamic mixer is dedicated to the continuous, uniform and gentle mixing of various liquids. Its unique stateless and low-shear design is particularly suitable for processing scenarios that are sensitive to shear, containing solid particles or fibers. With a simple structure and economical cost, NDM/E is an ideal choice for achieving efficient mixing and energy conservation and cost reduction in industries such as food, environmental protection, and chemical engineering.

Core functions: Gentle mixing, wide application

The NDM/E series achieves efficient and gentle mixing through rotors, with extremely low shear force, effectively avoiding damage to the structure of sensitive materials. This feature enables it to be widely applied in

Food industry: Evenly mix jam into yogurt or milk; Disperse the nuts and dried fruit particles completely in chocolate, ice cream or cake batter.

Water treatment industry: It is used for the preparation and addition of flocculants. Uniform mixing can significantly enhance the efficacy of the drug, reduce the dosage, save costs and lower the impact of chemicals on the environment.

Special process: Under specific designs, it can also be applied in industrial Settings such as the mixing of sludge and steam.

Main technical features

Gentle blending, quality guaranteed

The low-shear and low-energy consumption design ensures minimal pressure loss and no temperature rise during the mixing process, perfectly preserving the original properties and particle integrity of sensitive materials.

Simple structure, economical and durable

The stateless design fundamentally avoids the risk of clogging and ensures reliable operation. The simple structure significantly reduces the procurement and maintenance costs.

Clean and convenient, in compliance with standards

It meets the CIP (In-Line Cleaning) requirements and easily complies with the strict hygiene standards of the food, pharmaceutical and other industries.

Flexible and optional, with strong adaptability

The insulation jacket or electric heating function can be optionally equipped according to the process requirements, easily handling the mixing process that needs insulation or heating.

Why choose the NDM/E series?

Suitable for sensitive materials: The low shear property protects the product texture and is an ideal equipment for handling fluids containing particles and fibers.

Continuous and efficient operation: It enables uninterrupted production, enhancing efficiency while consuming much less energy than traditional stirring equipment.

Save comprehensive costs: Not only is the purchase threshold for equipment low, but it also brings long-term benefits to customers by reducing raw material waste (such as flocculants), lowering maintenance frequency and conserving energy.

The NDM/E series dynamic mixer, with its reliable, economical and flexible mixing performance, has become a key equipment for improving quality and efficiency in many industries. If you are looking for a hybrid solution that is suitable for sensitive materials and strikes a balance between efficiency and effectiveness, NDM/E will be your wise choice.

| NDM/E | ||||

| Type | NDM/E 100 | NDM/E 150 | NDM/E 200 | NDM/E 250 |

| Flowrate L/h | 100~3,000 | 500~10,000 | 1000~20,000 | 5000~60,000 |

| Speed rpm | 150~1450 | 150~1450 | 150~950 | 100~950 |

| Motor power kW | 1.5~2.2 | 2.2~5.5 | 3~7.5 | 3~11 |

| Connection | DN100/50 | DN125/65 | DN150/80 | DN200/100 |

| Viscosity cSt | 1~100,000 | |||

| Design pressures | PN20/PN40 | |||

| Material | 304L/316L/2205/2507 | |||

| Sealing | Cartridge Mechnical Seal/Double Mechnical Seal/Magnetic Drive | |||